Projects

The presented projects exemplarily describe our main scope of work. On request we would be pleased to compile reference projects especially for your task. Get in contact with us.

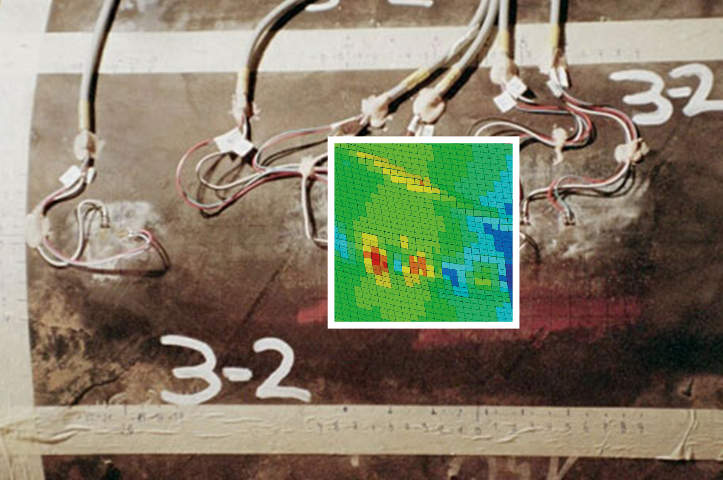

Condition assessment of hydrogen pipelines

Condition assessment of hydrogen pipelines

Transporting and storing hydrogen in the existing gas infrastructure is a promising contribution to the energy transition. In order to use this infrastructure safely and economically the specific characteristics of hydrogen must be considered. The engineers of VEENKER with their expertise support the gas pipeline operators in hydrogen issues.

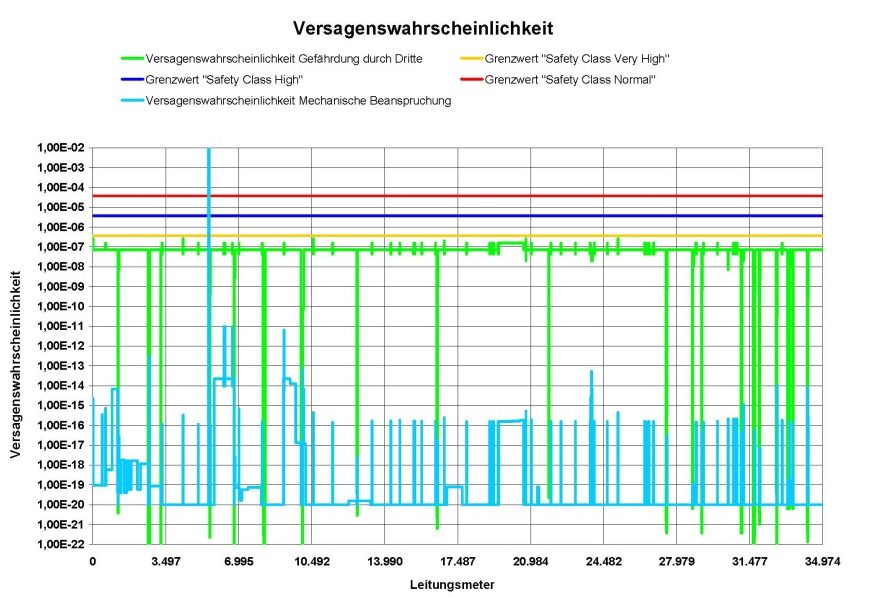

Pipeline Integrity Management System - PIMS

VEENKER developed a Pipeline Integrity Management System (PIMS) that, based on failure probabilities, can maintain pipeline integrity (safety) on the one hand and on the other hand exactly determine the necessary need for action (profitability) – individually tailor-made for the operator.

Risk for birds to be killed in wind farms

Are wind turbines dangerous for birds? There is no general answer available. However, for specific bird species the risk from a specific wind turbine can be determined. An expert report enables wind farm operators to meet the demands of the German Federal Act for the Protection of Nature and to obtain planning security.

Pipeline planning and assessment by means of SRA and QRA

There are numerous rules and regulations for constructing and operating a pipeline. However, a risk remains which can be quantified by specifying the failure probability or by verifying and assessing the consequences of a failure. This probabilistic assessment method is called SRA/QRA and enables pipeline operators to prove the safe operation of their existing or planned pipelines.

[more]

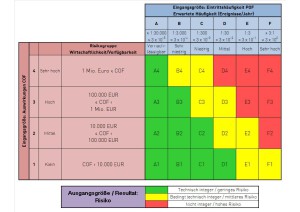

Risk assessment in the vicinity of wind turbines

Wind turbines can represent a safety risk. This safety risk should be assessed in the vicinity of objects which need to be protected, such as pipelines. Under the leadership of Enercon GmbH, Germany, VEENKER compiled a comprehensive general wind turbine expert opinion report. By means of this report individual cases can be assessed.

[more]

Practical solutions with liquid soil

The foundation of pipelines in accordance with the requirements – especially after repair or inspection measures – is generally difficult to handle as compacting added soil under the pipeline is complicated. A very good alternative is liquid soil, which was used by VEENKER successfully in several challenging projects.

[more]

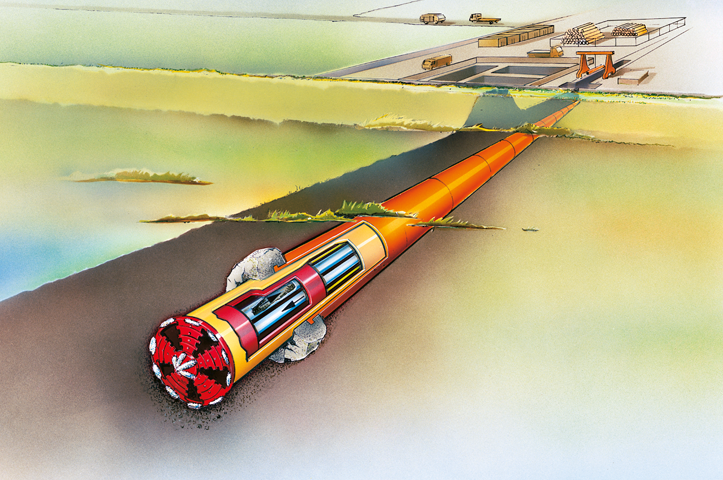

HDD method for pipeline crossings

In the course of the highway BAB A 7 development a long distance gas pipeline of Avacon AG was affected at two points. Avacon AG followed VEENKER’s planning and recommendation and gave priority to the HDD method (Horizontal Directional Drilling) for technical, safety and financial reasons.

[more]

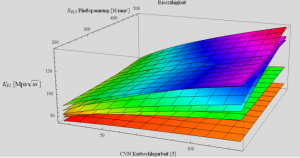

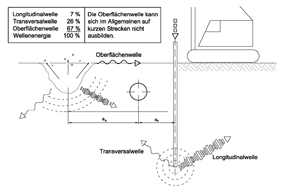

Reliability analysis for dynamic loads by means of DynRo

VEENKER developed a user-friendly software which enables the analysis of dynamic loads on high-pressure gas pipelines, e. g. due to ramming, vibrating, blasting or traffic. Answers to practical issues concerning dynamic energies and distances, e. g. to a pile sheet, are given in each individual case.

[more]

Lowering a high-pressure gas pipeline

The lowering of pipelines in endangered areas is state-of-the-art and can be carried out without any problems if corresponding investigations concerning additional loads and pipeline integrity allow this measure. VEENKER planned and supervised the lowering of a gas pipeline for Avacon AG.

[more]

Wadden Sea crossing for the Europipe

The Europipe from the Norwegian Troll Field crosses the Lower Saxon Wadden Sea National Park (Nationalpark Niedersächsisches Wattenmeer). VEENKER developed the “Teleskoppressung” (telescopic pressing) as a technical solution. Therewith the mud flats could be undercut horizontally by means of a double-walled tunnel-boring machine.

[more]

Storage Integrity Management System - SIMS

Together with renowned gas suppliers VEENKER developed a Storage Integrity Management System (SIMS). By means of SIMS, operators receive a tool for maintaining and managing the integrity according to objective criteria. SIMS minimises risks, ensures safety in planning and is cost effective.

[more]

Integrity of gas-related facilities thanks to TIMS

The Technical Integrity Management System (TIMS) developed by VEENKER helps to guarantee the faultless condition, the integrity of gas-related facilities. A TIMS minimises risks, gives safety for planning and is cost effective.