Integrity of gas-related facilities thanks to TIMS

The Technical Integrity Management System (TIMS) developed by VEENKER helps to guarantee the faultless condition, the integrity of gas-related facilities. A TIMS minimises risks, gives safety for planning and is cost effective.

Operators of gas-related facilities are legally obliged to guarantee integrity of their gas facilities. A Technical Integrity Management System (TIMS) assesses the condition of gas facilities and shows the need for repair and rehabilitation together with specific recommendations in time. Instead of having to carry out planned maintenance work according to a prescribed framework, the operator invests directly in safe operating of gas-related facilities by means of condition-based maintenance.

After complete stocktaking and assessing all relevant facility components (basic assessment) the next step is a regular condition assessment. Thus, integrity of the gas facility can continuously be verified. This enables the operator to plan medium-term and long-term rehabilitation and replacement of its facilities and to ensure future integrity of the facility. Thereby, VEENKER’s expertise brings with it a decisive competitive advantage.

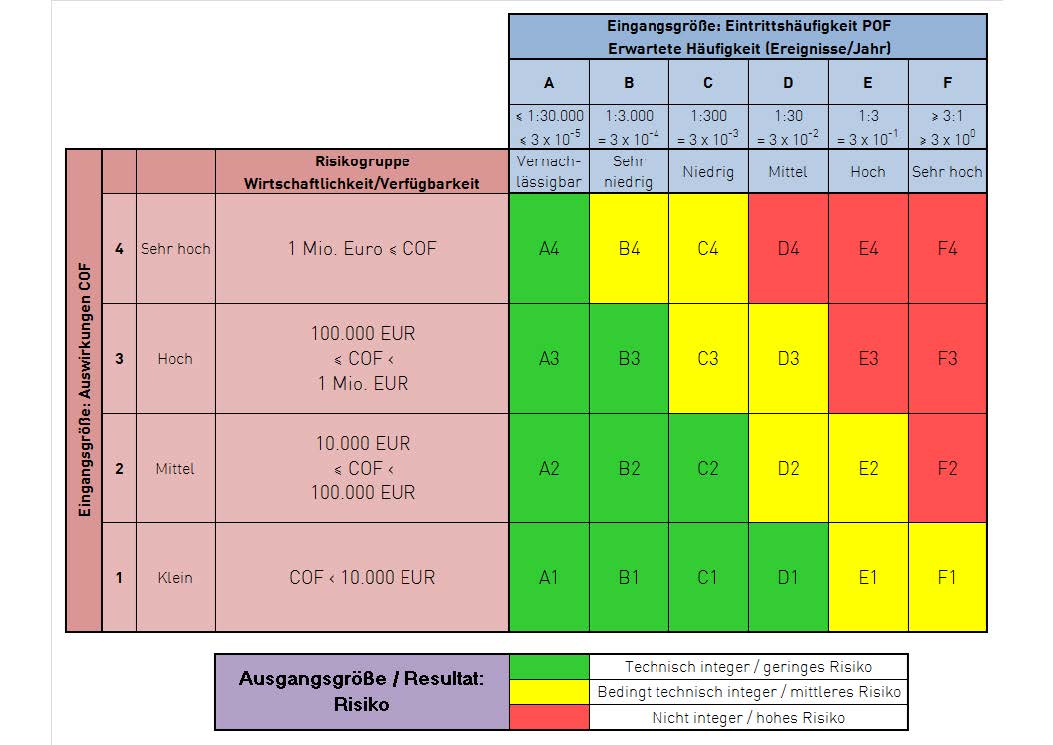

A TIMS must meet diverse requirements: It considers all significant data from data management systems, the operator’s experience and other sources. These data are assessed: Limit values and weightings are determined, risk matrices for cost effectiveness, safety and the environment are worked out, applied and all facility components which require action are shown. Based on the findings obtained weak points are identified and concrete plans for measures are worked out in accordance with a condition-based maintenance. By means of this, inspection and maintenance intervals, for example, can be optimally controlled and the spare part management can be improved. A further advantage that cannot be ignored: All decisions are objective and comprehensible.